Most electronic devices and circuits have resistors in them. Within an electronic circuit, the value of the current and voltage must be maintained and regulated. As the electric current flows through the circuit, the resistor creates resistance to limit the passage of the flow.

Types of Resistors

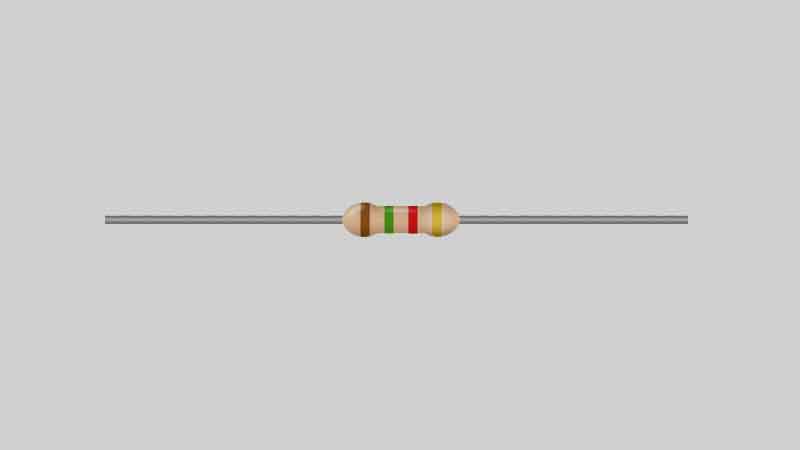

Ohm represents the unit of resistance used when talking about resistors. There are several types of resistors to choose from in the marketplace. Most people don’t realize this and just assume that all resistors are the same. This is not true because resistors are different based on their size and rating. You can always tell the difference between each resistor based on their color code.

Let’s go over the different types of resistors now.

1. Wire Wound Resistors

Wire wound resistors come in different sizes and aesthetics. Like the name indicates, these resistors are wires of about the same length which are made from copper-nickel manganese alloy, nickel chromium alloy, or some other type of alloy.

Wire wound resistors were the first type of resistors to ever be used. They are still used today because of their low resistive values and high-power ratings. You’ll find the wires of the resistors are enclosed within a finned metal case because they get extremely hot.

2. Metal Film Resistors

Metal film resistors are popular because they’re said to have better stability, reliability, and accuracy. The average metal film resistors are manufactured out of either ceramic-coated metal or metal oxide. They have a lot of the same properties as carbon-film resistors. However, the thickness level of their ceramic coating or metal oxide coating is what controls their resistivity.

3. Thick Film Resistors

Thick film resistors are more affordable than thin film resistors. They contain a thick film which serves as its resistive element. The thick film is 1,000 times thicker than the thin film. Manufacturers create thick film resistors by powered glass with ceramic materials.

4. Thin Film Resistors

Thin film resistors cost more money than thick film resistors. They have a resistive element of 1,000 angstroms, which means they have lower capacitance, lower noise, improved temperature coefficients, and lower parasitic inductance. You’ll find that thin film resistors are used in components which utilize microwave power. If high stability and high accuracy is required in an application, then it likely has thin film resistors.

5. Surface Mount Resistors

Surface mount resistors are available in various shapes and sizes. They are one of the few resistors which do not have color code bands on them because they’re so small. You could even get a surface mount resistor as small as 0.60mm by 0.30mm. Instead of color bands, they use numbers to indicate their value. They have an incredibly low 0.02% of tolerance as well.

6. Network Resistors

Network resistors use several different resistances to give each pin the same value. You can get these resistors in a single inline package or dual inline package. You’ll find network resistors used the most in analog to digital converter applications, digital to analog converter applications, pull up applications, and pull-down applications.

7. Variable Resistors

Variable resistors are used the most for dividing voltage and adjusting the sensitivity of electronic sensors. The resistance of variable resistors has a fixed value that exists in the middle of two terminals.

Read also:

- The Different between OTL and OCL Power Amplifiers

- 7 Different Types of Amplifiers with their Functions

- How does an Audio Amplifier Work?

Color Codes Explanation

The sides of the resistors have color bands which indicate certain values. The colors you might see include white, gray, purple, blue, green, yellow, orange, red, brown, and black. White represents 9, gray represent 8, and keep going until you get to 0 for black. Usually, you’ll see between 4 and 6 color bands on every resistor.

For example, if have 4 colored bands on a resistor, you would take the numbers of the first two bands and multiply them by the value of the third band. However, the value of the third band indicates how many zeroes go after the number one. So, if you had a red colored third band, this would indicate the number 2. Therefore, you would multiply the first two color band values by 100. Read full article below for more detail about resistor color codes reading.

Read Resistor Color Codes

As we mention above, The value and rating of any resistor can be determined by its color code. Every resistor has a sequence of colors on it. Each band has a number associated with its color. Here are the sequence of resistor color codes:

- Black: 0

- Brown: 1

- Red: 2

- Orange: 3

- Yellow: 4

- Green: 5

- Blue: 6

- Putple: 7

- White: 8

- Silver (Tolerance 10%)

- Gold (Tolerance 5%)

Here the simple example:

If you found the resistor with color strip:

red | red | yellow | gold

2 | 2 | 4 | 5%

2|2|0000| 5%

220000 ohm (-+ 5% tolerance)

So the measurement of resistor is: 220k ohm (-+ 5% tolerance)

Another simple example:

Yellow | Brown | Red | Green | Silver

4 | 1 | 2 | 00000 | 10%

41200000 (-+ 10% tolerance)

42.200.000 (-+ 10% tolerance)

42.1 mega ohm (-+ 10% tolerance)